News

Contact us

+86 0752-6664366

E-mail:FCL@jx-qst.com

Phone:180-0288-3443

Address:Qianping Industrial zone, Le 'an Industrial Park, Le 'an County, Fuzhou City, Jiangxi Province

Current status and performance requirements of three key raw materials for high frequency and high speed PCB copper-clad plates

In this paper, the supply chain pattern of special electrolytic copper foil, special resin, and special glass fiber cloth used in new and high-end substrate materials in recent years, and the new performance requirements of these three materials are described.

Since the beginning of 2020, the spread of the global novel coronavirus epidemic has caused serious changes in the supply and demand chain of China's copper clad sheet raw materials. Since the development of 5G, the substrate materials for high-frequency and high-speed circuits, high HDI and IC sealing and loading plates have also undergone great evolution in technology, performance and variety. In the face of these two important changes, in-depth research on the supply chain pattern of electronic copper foil, specialty resin and specialty glass fiber cloth used in new and high-end substrate materials, as well as new performance requirements for the three major materials, is considered to be very important and urgently needed work. This article makes some discussion in these two aspects.

1. Electrolytic copper foil

1.1 The supply status of various low-profile electrolytic copper foils and the new characteristics of the market pattern

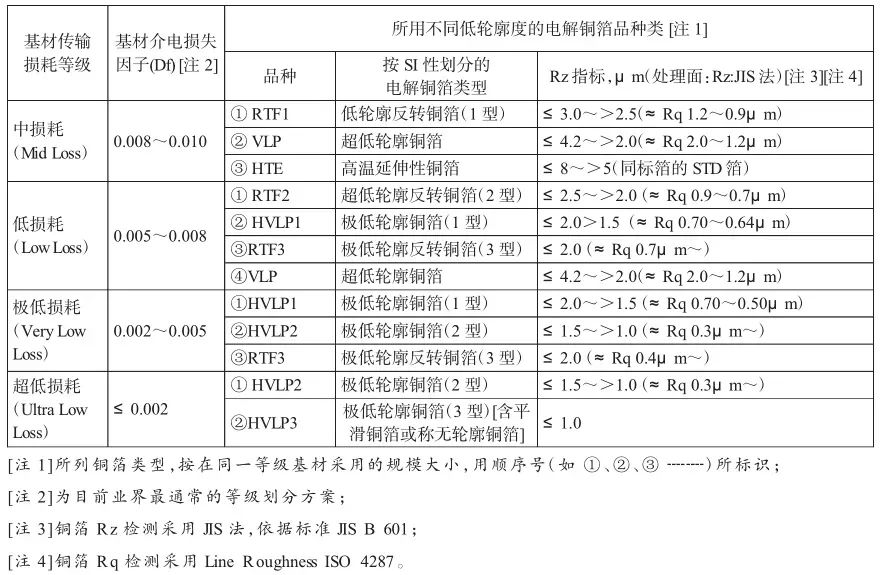

The size and pattern of the global high-frequency high-speed electrolytic copper foil market in 2019 (market share of various countries/regions and major manufacturers) are shown in Figure 1 and Table 1.

Figure 1. Size and pattern of the global low profile copper foil market in 2019

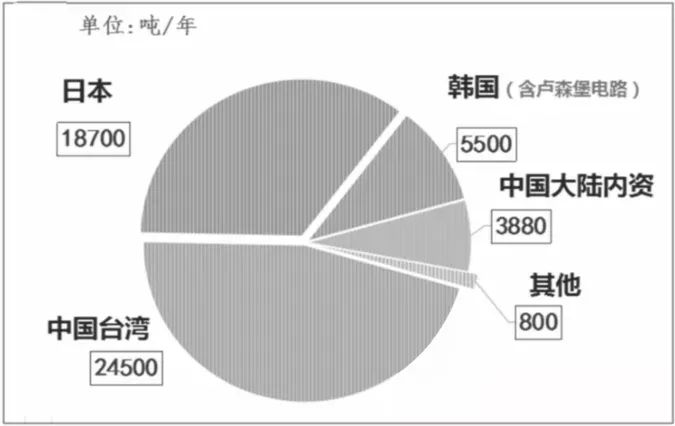

Table 1. Statistics and forecast of market pattern of low profile copper foil for high-frequency high-speed circuits in 2018 and 2019

As can be seen from Figure 1 and Table 1, the global production and sales volume of low-profile copper foil (i.e., market size) is estimated to increase by 49.8% in 2019, reaching 53,000 tons. It is estimated to account for 7.6% of the world's total electrolytic copper foil. In the global high-frequency high-speed electrolytic copper foil production and sales in 2019, the ratio of RTF and VLP+HVLP production and sales is about: 77:23. However, the proportion of VLP+HVLP will increase in the next few years.

Domestic enterprises low-profile electrolytic copper foil production and sales, accounting for the entire domestic enterprise electronic circuit copper foil production (144,000 tons) of 2.7%. In 2019, domestic enterprises to achieve VLP+HVLP varieties can achieve a new breakthrough in mass production, but the production and sales of such low-profile copper foil is very small, accounting for only 2.3% of the global total production and sales of such electrolytic copper foil.

1.2 New differentiated characteristics of low-profile electrolytic copper foil varieties and performance requirements for high-frequency high-speed circuits

1.2.1 Electrolytic copper foil varieties and low profile properties corresponding to high-frequency high-speed copper-clad plates with different transmission loss levels

In order to pursue high frequency high-speed circuits with better Signal Integrity (SI), copper clad plates should achieve (especially at high frequencies) lower signal transmission loss performance. This requires copper foil, the conductor material used in the manufacture of copper clad plates, to have the characteristics of low profile. That is, the copper foil used in the manufacture of copper clad plate is low Rz, low Rq and other varieties.

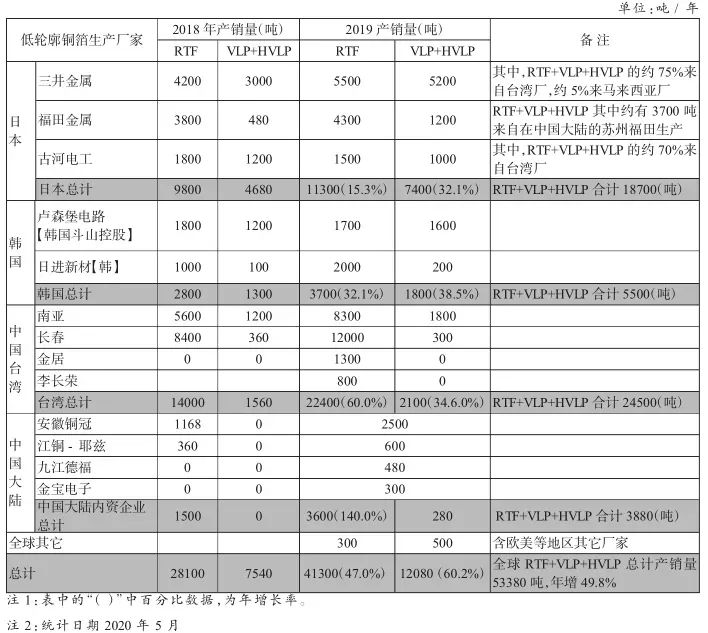

According to the four signal transmission loss levels, corresponding to the use of various low-profile copper foil varieties, Rz requirements and main manufacturers of brands, see Table 2. Table 2 also lists the ranking of the requirements of various varieties of low-profile copper foils in the substrate transmission loss grade copper clad plate.

Table 2. Rz index ranges of several electrolytic copper foils corresponding to high-frequency high-speed copper clad plates with different transmission loss levels